Selecting the right disinfection

When it comes to ensuring that surfaces, particularly those made of stainless steel, are free from pathogens and contaminants, selecting the correct disinfectant product is paramount. Infection prevention programs must ensure that high-touch areas, equipment, and surfaces can be promptly and effectively disinfected.

Due to its potent disinfectant properties, liquid bleach (sodium hypochlorite) has been a go-to option for many years. However, recent research underscores potential concerns associated with its repeated use on stainless steel surfaces.

According to an article titled “Are your stainless steel surfaces being corroded by repeated bleach use?” by Wendy Hollands and Jay Postlewaite from Texwipe, there’s a more efficacious alternative: Sodium Dichloroisocyanurate (NaDCC). (1)

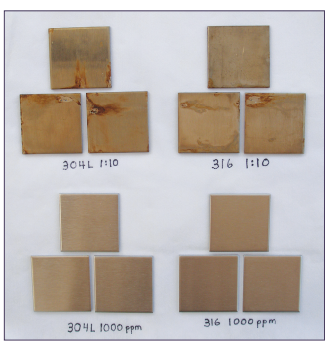

Stainless steel coupons exposed to bleach and sodium dichloroisocyanurate (NaDCC)

During the study, coupons were fully submerged in beakers containing 250 ml of each test solution noted above and wrapped in plastic. The coupons were removed daily, dried and visually inspected; differences were recorded and photographed.

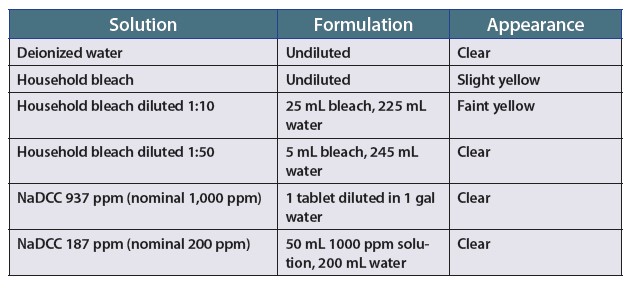

Table 1 below indicates the test solution formulations used in the corrosion study.

Test solution formulations Credit: Controlled Environments

Test solution formulations Credit: Controlled Environments

Stainless steel coupons exposed to bleach and sodium dichloroisocyanurate (NaDCC)

Coupons were fully submerged in beakers containing 250 ml of each test solution noted above and wrapped in plastic. The coupons were removed every day, dried and visually inspected; differences were recorded and photographed.

Stainless Steel Corrosion

The research by Hollands and Postlewaite indicates that repeated bleach application on stainless steel can lead to corrosion. Corroded surfaces, apart from looking unsightly, can harbor pathogens in the tiny pits and cracks. This directly compromises the very reason for disinfection in the first place. NaDCC, in comparison, does not have the same corrosive effect on stainless steel, making it a safer long-term choice.

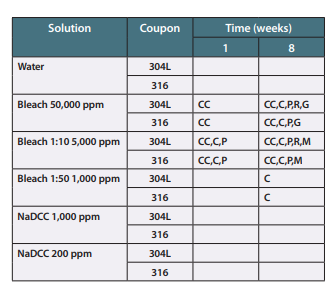

Table 2: Physical changes summarised weekly

The above table observes the physical changes summarised by week.

Key:

- C = Corrosion, the beginning of observation corrosion.

- CC = Color change; the silver metal changes to slightly orange or darker.

- G = Gas evolution, bubbles of gas evolving from the metal are visible in the solution.

- M = Metal deposition, dark and also shiny deposition on the beaker wall.

- P = Pitting, divots in the metal surface.

- R = Rust, a red, flaky material on the coupon face or edge or a deposit on the bottom of the beaker.

Continuous use of Bleach

The following bleach concentration levels are the standard operating procedures typically used in the pharmaceutical, medical device and bioprocessing industries. As per visual steel coupons, continued use of bleach as a part of an infection prevention program may cause equipment to corrode and discolour.

The above coupons were exposed to concentration levels of 1:10 bleach and 1,000ppm NaDCC. Notice the discolouration and corrosion of the bleached solution coupons 304L and 316 1:10.

NaDCC Ease of Use:

According to the article by Hollands and Postlewaite, NaDCC tablets can be easily dissolved in water to achieve the desired concentration. This user-friendly approach ensures consistent and accurate dosing, minimizing the risk of under- or over-concentration that can happen with liquid bleach.

NaDCC Efficacy:

Click here to find a study on the effect of our NaDCC chemistry against C.diff.

Stability and Potency:

NaDCC has been observed to have a more stable and prolonged shelf life compared to bleach. This means that even after being stored for extended periods, NaDCC maintains its disinfectant potency. Bleach, on the other hand, loses its efficacy more quickly over time. Our NaDCC disinfection tablets carry a 3-year shelf life.

Less Irritation:

A solution of NaDCC has a pH of 6.0 to 7.0, similar to skin, whereas bleach has a pH of 12 to 13, making NaDCC less likely to irritate when used.

Reduced Storage Concerns:

Since NaDCC effervescent tablets are in solid form, there’s no risk of spillage or leakage, making storage and handling safer and more convenient.

Reduced Shipping

Transporting liquid bleach can be costly, whereas a pallet of NaDCC tablets can create approximately forty-six thousand 489 liters of hospital disinfectant @ 4306ppm.

Kersia NaDCC cleaning and sanitizing products have been trialled, trusted and approved for their:

👉Germ-killing power.

👉Broad-spectrum protection.

👉 Fast action.

👉Versatility.

👉 Ease of use.

👉 US EPA-compliant.

👉 Ideal for those committed to maintaining a safe and healthy environment.

While bleach has had a long-standing history as a disinfectant, it’s essential to be aware of its limitations, especially concerning repeated use on stainless steel surfaces. The research presented by Wendy Hollands and Jay Postlewaite emphasizes the superiority of Sodium Dichloroisocyanurate (NaDCC) in terms of efficacy, safety, and long-term benefits. It’s a timely reminder to reconsider disinfectant choices, weighing the long-term implications alongside immediate disinfection needs.

Ref:

(1)https://asia.texwipe.com/Content/Images/uploaded/documents/Disinfectants/Stainless_Steel_Bleach.pdf

Contact our infection prevention experts for more information on Kersia NaDCC products:

Kersia Healthcare 2023